Metal etching net processing problems and causes

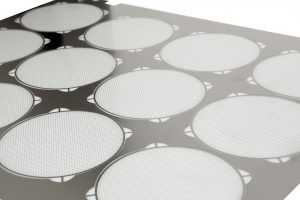

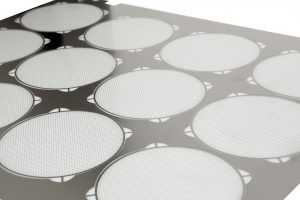

The metal etching network is formed by an etching process, which is widely used in precision filtration system equipment, electronic equipment parts, optical, medical equipment and instruments. Metal mesh with etching process generally has the characteristics of small aperture, dense arrangement and high precision. Therefore, we should pay attention to the quality control during the production process. Today, we will introduce the problems that are easy to occur in metal etching network processing. the reason.

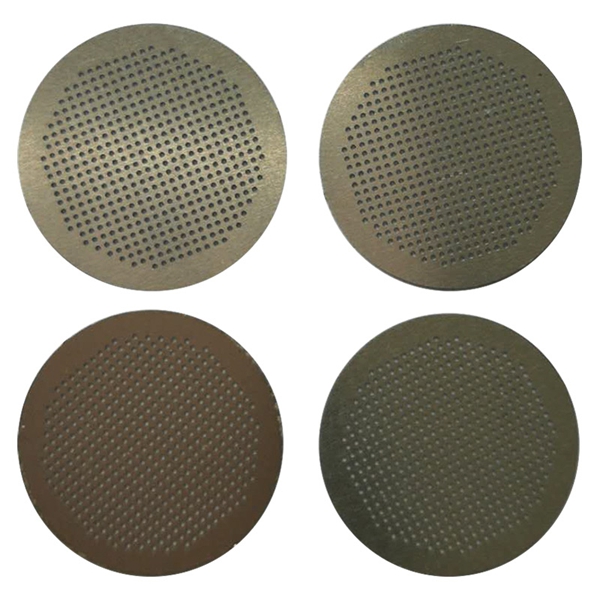

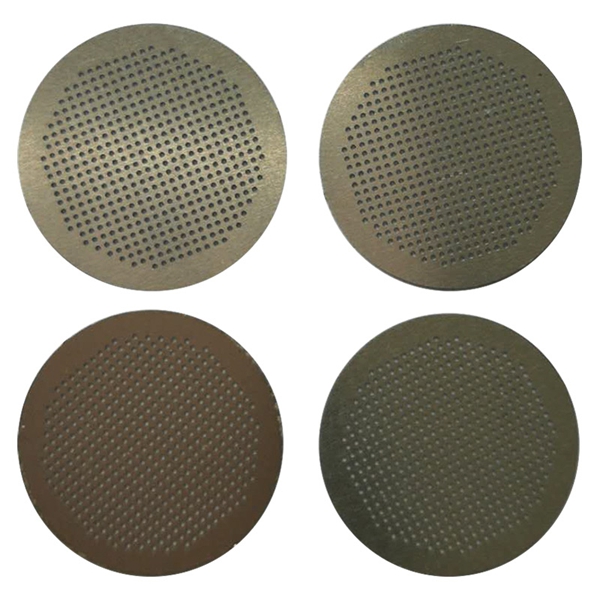

In the precision etching network processing, there are two problems that are easy to occur for the whole industry, that is, blind holes and plugging holes. In particular, mesh-intensive products are mainly due to the small pore size of these products (some even up to 0.05 mm), and one is densely packed. Then, after exposure and development, there is a certain difficulty in detecting the product. Thousands of holes are difficult to be inspected comprehensively, and it is easy to generate plugging holes and blind holes. Therefore, for dense metal etching mesh, the industry generally allows 6%. Blind hole.

If it is more than 6% or even higher than 8% of plugging holes and blind holes, then this is a bad production, which is not in control during the etching process. For example, the dust-free workshop can't meet the requirements, and dust and stains enter the ink. Or in the exposure developing device, causing inaccurate large-area etching groups, resulting in inaccurate development, resulting in metal etching mesh plugging holes and blind holes.

In addition, the surface of the metal etching net is rough and not smooth after processing. There is no need for corrosion in the corroded part, and the surface is white and the touch is not smooth. This is mainly because the surface of the metal raw material is not cleaned, resulting in a decrease in the adhesion of the photosensitive ink, and a warp film is formed after baking, and a certain amount of corrosion is generated in the embossed portion during the etching process.

The above is the problem and the reason that the metal etching net processing is easy to occur. For the metal etching net processing, the control of any process is not in place, which may cause the product to be bad. Therefore, when looking for the metal etching net supplier, it should be the factory Strength to do an understanding, choose a company with strong comprehensive strength.