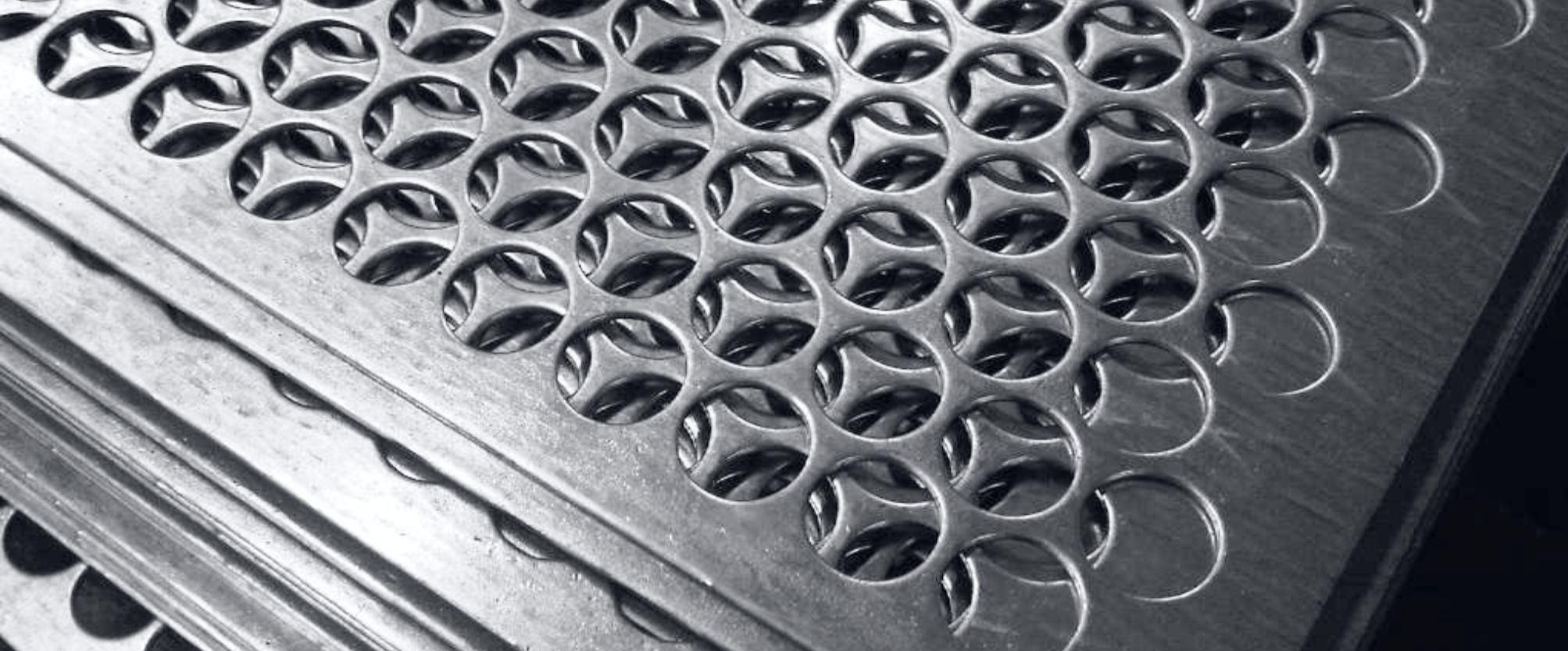

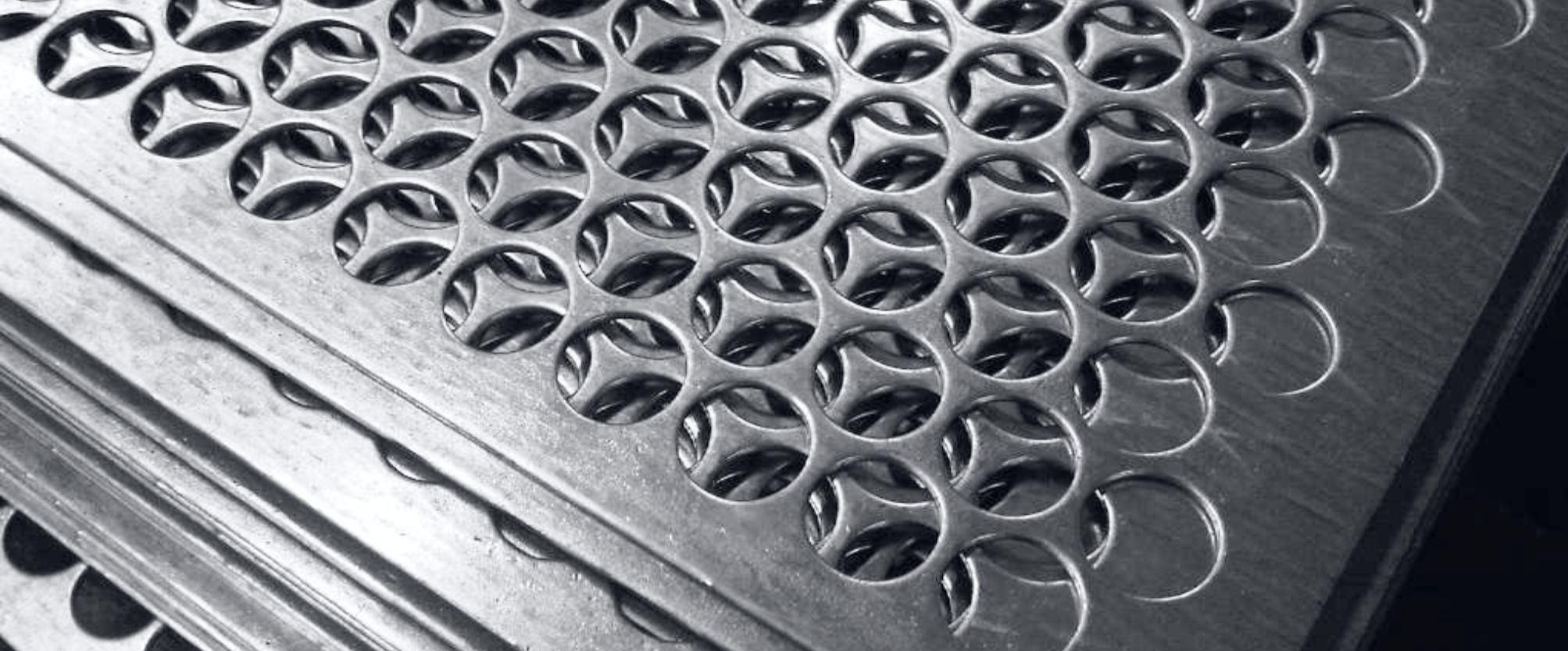

Q345 Steel plate perforated net

Everyone knows that the so-called manganese steel is the current Q345 material. It is also a common processing substrate for perforated mesh products. Manganese steel is a high strength steel. Its most important feature is that under strong impact extrusion conditions, the surface layer rapidly undergoes work hardening phenomenon, still maintaining the good toughness and plasticity of the central austenite, while the hardened layer has good wear resistance. This is the unique nature of the product. However, the wear resistance of high manganese steel can only show its superiority when there are sufficient conditions to form work hardening, while in other cases it shows very poor wear resistance. Manganese steel is particularly suitable for impact abrasive wear and high pressure crushing of abrasive materials. It is commonly used in the manufacture of ball mill liners, hammer crusher heads, tractor and tank track plates, and other impact and wear resistant primary keys. It is also suitable for bullet-proof steel plates, safety steel plates, etc.

In China, many German iron ore producers, regardless of size, need porous plates to screen out different sizes of raw iron ore. Perforated mesh refers to different shapes of holes punched in the same material to suit different needs. It can be used for environmental noise control barriers in highways, railroads, subways and other transportation and municipal facilities that cross urban lots, sound-absorbing panels for noise insulation and noise reduction in building object walls, generator rooms, factory plants, and other noise sources. This kind of sieve plate is generally used as the raw material of manganese steel, and its thickness requirement is generally above 6 mm before the line. This kind of sieve plate is durable and not easy to wear, and it is a good choice for sieving ore in the mine. But as we all know, manganese steel is characterized by very strong and hard steel, which is difficult for us to punch, so how can we overcome these problems?

Manganese steel perforation is a perforated network formed by perforated manganese steel plate in the process of manganese steel perforation, and the crimping force of the product plays a big role. Perforated plate is also known as perforated mesh, porous plate, perforated plate, mineral screen, machine screen, etc. As the name implies, it is a metal plate with various types of shaped holes on the surface Product uses are widely used in various industries such as chemical machinery, pharmaceutical equipment, food and beverage machinery, tobacco roll machinery, harvesting machines, dry cleaning machines, ironing tables, silencing equipment, refrigeration equipment (central air conditioning) speakers, handicraft production, paper making, hydraulic fittings, filtering and clearing equipment. The crimping force we are discussing is the reinforcement of the material on the end face of the concave die to prevent warping of the surrounding scrap so that the compressive stress during zero clearance shearing is not reduced by the backing off of the material, thus increasing the compressive stress on the material near the end of the lower die. Prevent cracks from the edge of the lower die. As the crimping force of manganese steel perforated mesh increases, the shear band of the punched products decreases. The crimping force varies with the structure and distribution of the teeth on the crimping plate, but the crimping force is 30-50% of the crimping force. Excessive crimping force of manganese steel blanking mesh in the blanking process will not only improve the quality of the fracture, but also shorten the service life of the die. Therefore, we must control the crimping force in place in our production and processing, so that our manganese steel sheet punching mesh products are more stable and durable.