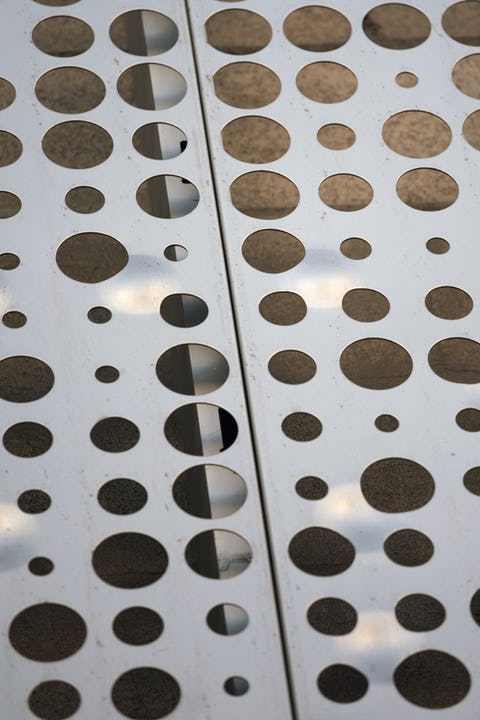

We usually use electroplating, hot plating, plastic spraying and other methods to deposit a layer of metal that is not easily eroded, such as zinc, tin, chromium, nickel or electrostatic powder on the surface of the punching net. This method is mainly used to prevent products in soil, sea water and river water from being eroded.

Cover the product with a protective layer to isolate the product from nearby erosive media to prevent erosion. Apply corrosion-resistant non-metallic materials such as engine oil, cutting fluid, paint on the surface of the product. The principle of galvanic cell is used to protect the metal, and the idea is to eliminate the galvanic cell reaction caused by electrochemical corrosion. It can effectively block or prevent the product from being corroded in acid, alkali and salt. To eliminate erosive media, the electrochemical protection method is divided into two categories: anode protection and cathode protection. Such as forming a fine black iron oxide thin film on the surface of the product. After energization, the surface of the perforated net generates a negative charge accumulation, which suppresses the metal loss of electrons and achieves the purpose of protection. So how do we deal with it?

First remove the protective film on the surface layer. There is a fine oxide film on the outer surface of the perforated mesh. Its purpose is to protect the product from oxidation. So how do we remove it, we can soak it in a strong alkaline solution (such as 40% sodium hydroxide solution) to 40 ° for about half an hour. You can remove the oxide film from the surface. The purpose of electrolysis is to generate a new loose oxide film. The electrolyte uses 20% dilute sulfuric acid, connect the aluminum parts to the cathode, and use 12v-15v direct current for electrolysis for about one hour. Then coloring is carried out, and the electrolyzed product is put into the dye for coloring. Curing, using professional curing agent to cure the product. Finally, spraying is carried out, and the punching net is sprayed with electrostatic powder. The product after spraying not only uses more time, but also its surface is very bright, improving the quality of the product.

Contact: David Liu

Phone: 0086-18831823993

Tel: 0086-318-5289565

Email: david@weiyuemesh.com

Add: NO.18, WARP3 ROAD,ANPING COUNTY,HENGSHUI CITY,HEBEI PROVINCE,CHINA