In what ways are perforated mesh panels outstanding?

When you use the perforated mesh panel in the process should be able to find its advantages are very much, especially the performance aspects generally will not let you down. Today, I am here to analyze its performance advantages in detail for you, so that you can better apply perforated mesh panels afterwards.

Perforated mesh panels are made from a variety of raw materials, such as galvanized steel, stainless steel, aluminum, alloy plates, etc., and are made using molds. The beauty of perforated mesh panels is very high, the size of the round holes is consistent, the surface is smooth and flat, very easy to process, and the cost is very low.

From the perspective of raw materials, it can be divided into galvanized steel, stainless steel, nickel plate, etc. Another feature of perforated mesh panels is that they have a raised pattern on the surface, which makes them significantly more non-slip; the raised pattern is cross-shaped, which can bring convenience to CNC processing.

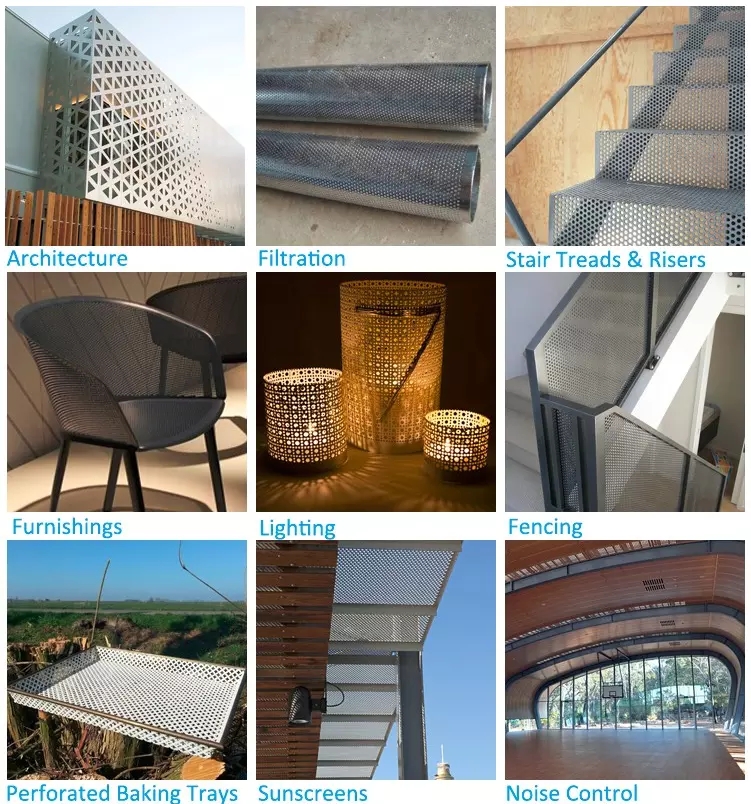

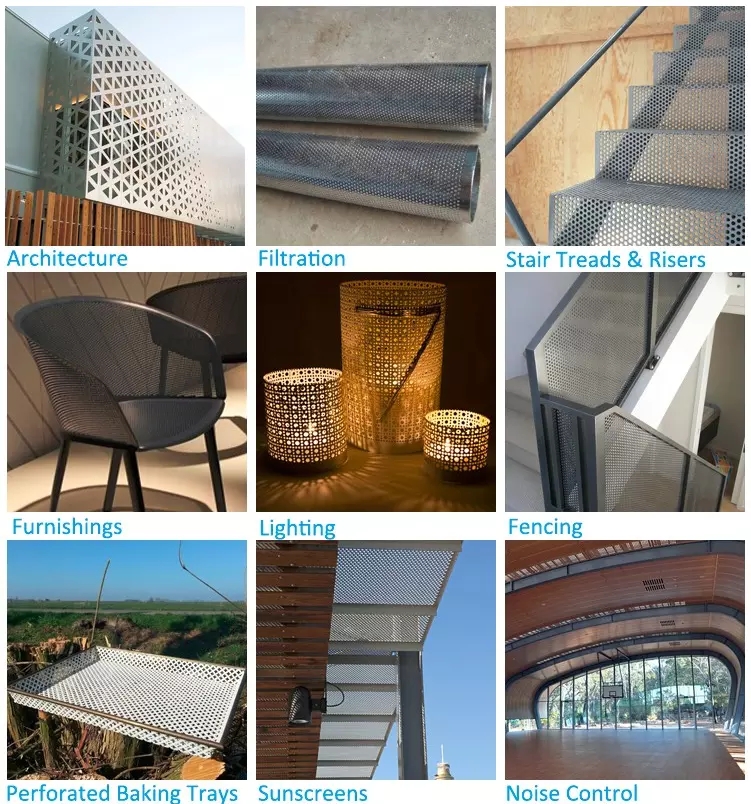

Perforated mesh panels are used in a wide range of applications, such as water plants, power plants, sewage treatment plants, stepping plates, and as anti-skid raw materials. The round holes on the perforated mesh panels are evenly distributed and uniform in size, which is very nice and interesting to look at.

Perforated mesh panels are generally used in amplifiers, speakers, loudspeakers, and can also be used as shields for small machines, protective covers, etc. Perforated mesh panels can also be used as filters, the kind of mesh with very small holes, so that the effect can be very good.

Translated with www.DeepL.com/Translator (free version)