Why do we need to perform surface treatment on the perforated mesh?

The benefits of surface treatment for perforated plate mesh are very many. If you do not know why it should be surface treated before, you can take a look at the detailed method introduced in the following article, and I believe you will know very well what are the benefits of surface treatment for perforated plate mesh after reading it.

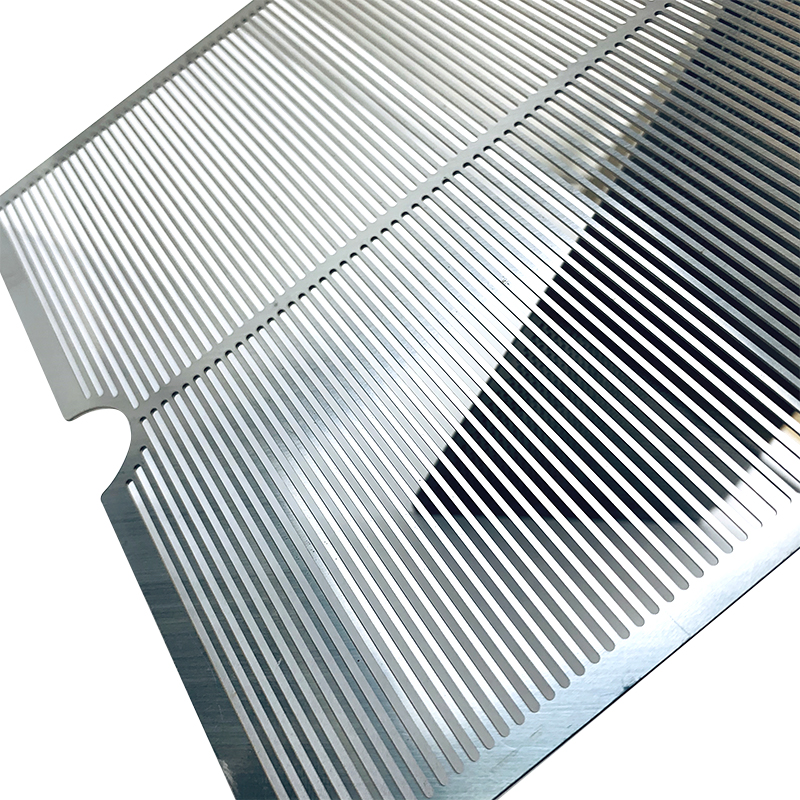

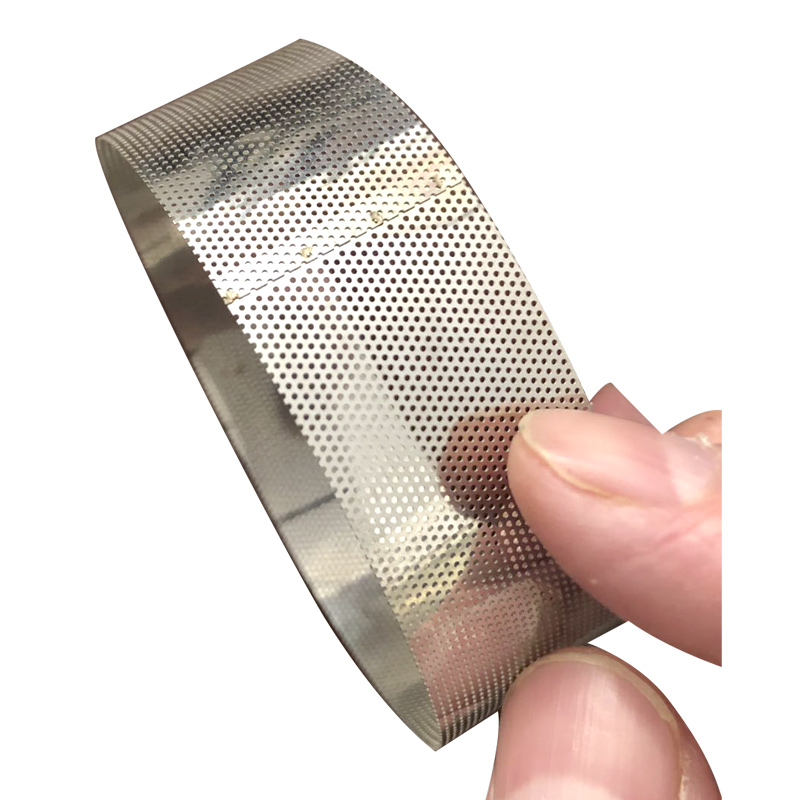

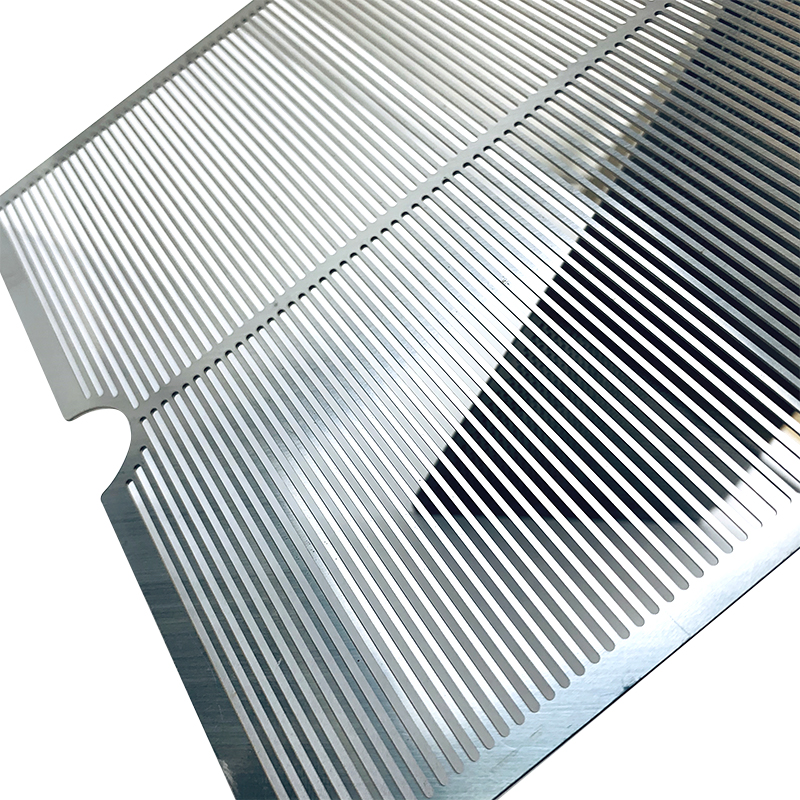

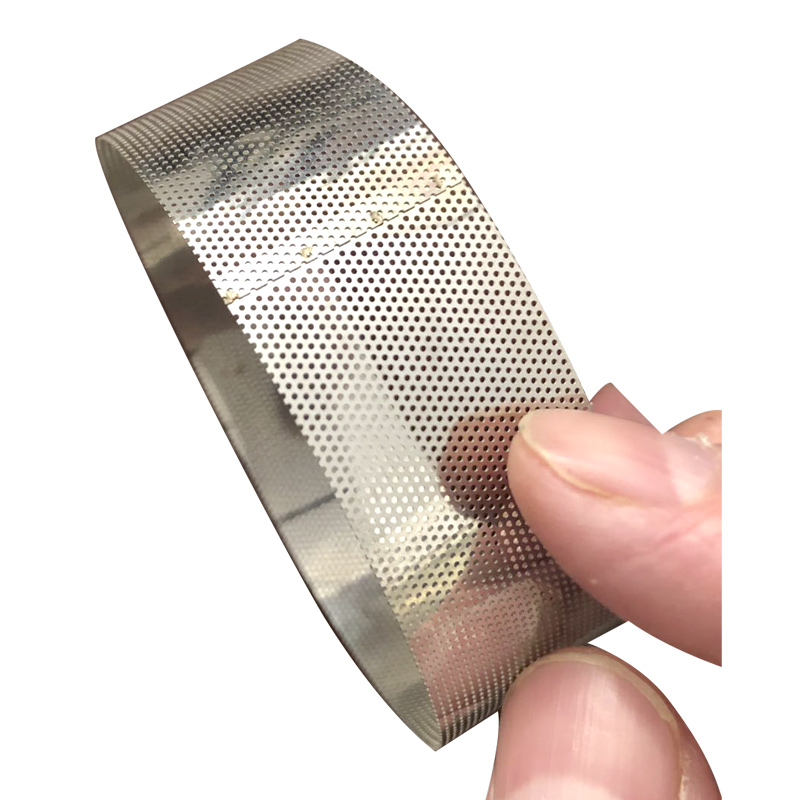

The basic material of perforated plate mesh products is mainly metal, metal is easy to corrode and rust if exposed to the air for a long time, which not only affects the beauty of the product, but also greatly reduces the service life, so the manufacturers will generally carry out anti-corrosion treatment on the surface of perforated plate mesh products.

There are several common surface treatments: galvanizing, oxidizing, wire drawing, plastic spraying and painting. After the surface treatment, the perforated plate mesh products not only improve the decorative performance, but also have the advantages of corrosion resistance, acid and alkali resistance, not afraid of scratches, and extended service life.

The most commonly used surface treatment process is spraying, which makes the surface of perforated plate more polished, smooth to the touch and even on the surface. Generally, the perforated plate mesh products with plastic spraying treatment are mostly used in decoration design, mechanical equipment, sound-deadening equipment, food equipment, office furniture, curtain wall design, etc.

The above is the importance of surface treatment for perforated plate mesh, you will find that in the subsequent use of its performance is more stable and superior, there are many benefits.

Translated with www.DeepL.com/Translator (free version)