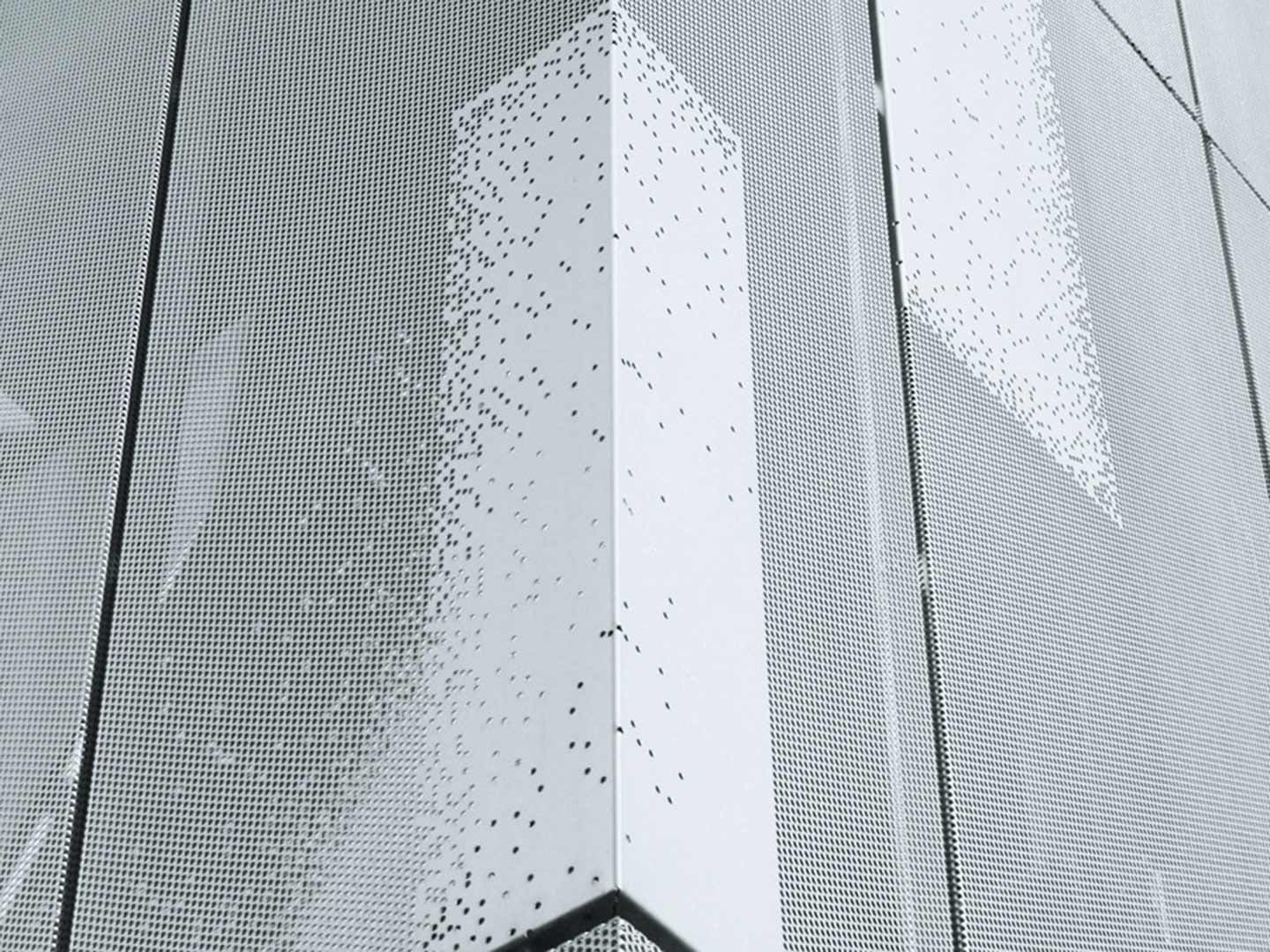

The structure of the product is perforated panel and perforated backplane, which is directly bonded into aluminum honeycomb sandwich structure by high-quality adhesive aluminum honeycomb core, and a layer of sound-absorbing cloth is pasted between the honeycomb core and the panel and the backplane. After processing, the plastic spraying is carried out by electrostatic powder spraying. Not only the service life of the processed product will be greatly increased, but also the spraying technology can change the color according to the customer's requirements, which is ornamental.

The principle of noise reduction of the perforated mesh: Since the honeycomb core in the honeycomb aluminum plate is divided into many closed cells, the air flow is blocked, the sound wave is hindered, the sound absorption coefficient is improved, and at the same time, the strength of the plate itself is improved, so that the single plate The size can be made larger, which further increases the design freedom. We can design different perforation rates according to the indoor acoustic design, and control the sound absorption coefficient of the combined structure within a certain range, not only to achieve the design effect, but also to reasonably control the cost. At the same time, by controlling the aperture and hole distance of the punching network, the punching rate can be changed according to the customer's requirements, but the theoretical maximum perforation rate is less than 30%, and the hole diameter is generally 2.0mm, 2.5mm, 3.0mm and other specifications. Between 2mm-3mm. The requirements of the perforated mesh backboard are the same as the panel, and the sound-absorbing cloth adopts high-quality non-woven fabric and other sound-absorbing materials.

Contact: David Liu

Phone: 0086-18831823993

Tel: 0086-318-5289565

Email: david@weiyuemesh.com

Add: NO.18, WARP3 ROAD,ANPING COUNTY,HENGSHUI CITY,HEBEI PROVINCE,CHINA